Dura-Bond offers an extensive portfolio of replacement and performance parts which have a long track record of being best in class. Quality products coupled with consistent high order fill rates set us apart from the competition. This is only possible by having the best resources, technologies and people in the industry.

We would like to work with you. Not just as a “production supplier, but as a strategic partner. If your requirements range from prototypes to high volume, let Dura-Bond be part of your solution.

History of Dura-Bond

Palo Alto Plant

Manufacturing began in the spring of 1947 in a small former woodworking plant in Palo Alto, California’s industrial section. After destroying 50 percent of early production due to flaws, Dura-Bond finally delivered it’s first 5,000 unit order and set a goal of 20,000 unites a month. Quite simple, they began to fill a growing need. The staff quickly learned that when a mechanic replaced an old camshaft bearing, he hammered the new one into place – requiring force to square the end away. Oftentimes the hammering created nicks along the edge resulting in a damaged bearing. Dura-bond’s idea was to make it a solid circle of metal, which inserted easily and fit perfectly. The “all-round” design of solid metal soon replaced the interlocking design as an industry standard. The breakthrough meant no oil loss – no seepage from bearing onto shaft.

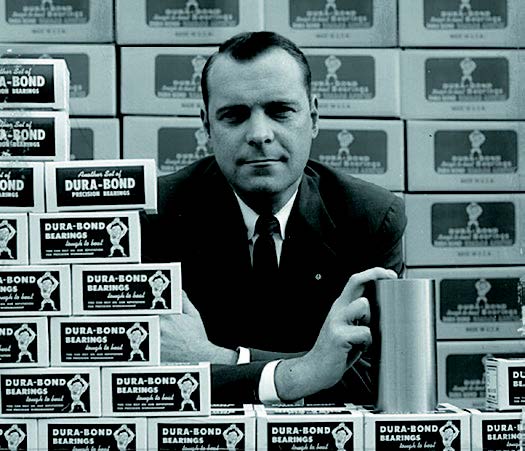

Though originally designed for replacement purposes in cars and trucks under the leadership of Franicis R. Burke, a Harvard graduate, Dura-Bond cam bearings quickly expanded into many specialized applications, such as: marine, farm equipment, antique vehicles, and more. Enduring products have included standard, aluminum overhead, and high performance bearings. More recent additions to the product mix have resulting from the purchasing of a well-respected valve seat manufacturer. In late 1996, Dura-Bond began offering high quality valve seat inserts designed for unleaded fuels with superior machinability.

Franicis R. Burke

Carson City Facility

Today over 70 years later, Dura-Bond has grown into a sophisticated 85,000 square foot facility located in Carson City, NV. It’s employees are among the most qualified engine rebuilding component technicians in the world. Current production and distribution sources include a long list of distributors, engine rebuilders, and original equipment manufacturers throughout Americana and abroad. Since its humble beginnings, Dura-Bond’s “all-round” camshaft bearings has assumed the enviable position of being the industry’s standard against which all others are judged.

Dura-Bond continues in the fine tradition it has developed over 70 years with its employees, customer and vendors. Our customers depend on our quality and innovative products to provide ever-increasing demands to provide solutions. These solutions range from all the basics of just-in-time delivery, quality – ISO 9001 certifications, Oliver Wight Class “A” MRP II and competitive pricing, and engineering design.

According to President/Owner, Charles Barnett, Dura-Bond Bearing company strives to exceed the exceptional level of quality and service that the company has maintained during the last 70 years. Says Barnett, “Our commitment to excellence and dedication continues to strengthen our customer relationships. These loyal customers are the reason we are still here, and the reason why we’ll be around to see another 70 years.

Charles Barnett

1947

Manufacturing began the spring of 1947 in a small, former woodworking plant, in the industrial section of Palo Alto, California. After destroying 50%...

1974

Started in Seattle, Washington by owner Lyle Snyder, Snyder Industries began producing valve spring booster shims. In 1980...

1987

After 30 years in Palo Alto, California area, Dura-Bond grew out of their facilities and the area which was changing to hi-tech industries...

1995

Chevrolet celebrates “A Tribute to the Engineers” and 40th anniversary that developed the famous “Chevy small block” at the Performance Racing Industry...

1996

In late 1996, Dura-Bond purchased Snyder Industries, Seattle, Washington. The plant was moved into the Carson City, Nevada facility and began...

1997

Dura-Bond celebrates “50-years” in business. Part of the celebration was to refurbish a 1954 Chevrolet pick-up to use at the trade show displays...

1999

Dura-Bond reached two major milestones - ISO 9001 certification and Oliver Wight Class “A” MRP II. Our goal has been to be a great manufacturer...

2002

Dura-Bond Bearing - Proud sponsor of the Melling #92 Dodge. 2002 NASCAR Driver Stacy Compton.

2016

Proud sponsor of the Plymouth Arrow 340 Mopar Naturally Aspirated #E-129 NHRA National Dragster...